When it comes to printed circuit boards, Rigid Flex PCBs are definitely the more precise and advanced technique that is used in the PCB manufacturing industry. Because of the flexibility and the advantages, they offer, the rigid-flex PCB market is expected to grow rapidly year by year.

In this article, we will be guiding you all about what is rigid flex PCB, how they come into being, their advantages and their future.

What Are Rigid-Flex PCBs?

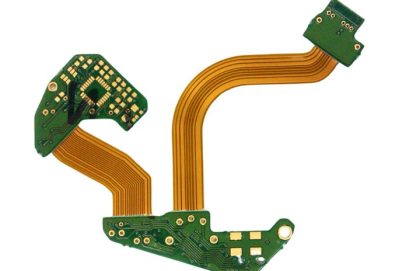

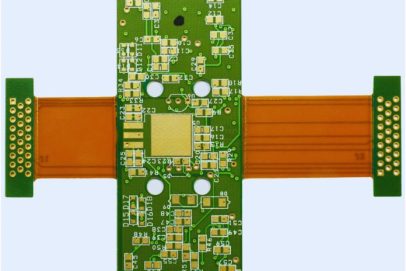

Rigid flex PCB is a special kind of printed circuit board that combines both rigid PCB and flexible PCB together to be one single PCB. So rigid flex circuit boards can utilise the benefits of rigidness from rigid PCB and flexibility of flex PCB.

Complicated electronic components can be assembled on the rigid part to meet the multifunction of today’s demanding electronic devices, and flexible parts can make sure the PCBs can be bent, twisted or turnover.

Flexible layers can be designed in inner layers or outer layers. But flex layers are usually designed in the inner layers to be symmetry, which is easier in production and also cost-effective.

Do you know that designs for rigid-flex boards are tougher than they appear? It is because they are created within the constraints of a 3D space, with higher spatial efficiency. It is not an ordinary person’s job to create rigid-flex boards.

Hence, you need a competent designer and experienced PCB manufacturing services provider for such a project. Only an experienced designer can achieve the desired shape and functions for the application package by applying the right technique. And only experienced PCB manufacturers can fabricate rigid flex circuits to be free of any errors.

The Evolution Of Rigid-Flex

Now that you know what rigid-flex PCBs are, let’s explore how they came into existence.

You would be surprised to learn about the history of rigid-flex PCBs in technical development. Printed Circuit Boards (PCBs) have been around for a while now. Actually, it was in the early 1900s when the whole idea of PCB saw the light of the day. In the beginning, PCBs were providing electric paths etched into individual surfaces for products such as gramophones and radios.

It was the through-hole technique in the 1960s that brought a shift into the world of PCBs. Only after the development of this technique, did multilayer circuit boards PCBs become a thing.

In response to the market needs, companies began designing and producing all kinds of PCBs. The primary objective was to develop customized products to satisfy the clients with multiple functions. One of the innovations was rigid-flex boards in the 1990s.

In the older design methods, layers were joined together using adhesives to construct rigid-flex PCBs. And because the adhesives’ thermal coefficient was very high, this was a serious problem.

This created stress for the manufacturers throughout the thermal cycle because it could lead to cracks in the copper plating over the via holes. A solution to this problem was the invention of new polyimide material and new production methods to further strengthen rigid-flex PCBs.

Nowadays, with the development of more advanced rigid-flex materials, such as polyimide material, no-flow prepreg, and high TG FR4, very complex rigid flex circuit boards can be produced, such as higher layer rigid-flex PCB, HDI rigid flex PCBs with blind and buried vias.

The Advantage Of Rigid Flex PCBs

If you compare the modern-day Rigid-Flex PCBs with the traditional ones, you will definitely notice major differences. For your ease, we have listed certain advantages of Rigid Flex PCBs.

● Better Flexibility

Rigid Flex PCBs that are currently available in the market are more flexible. This means that they are adaptable to the current trends and you can have the type you want for your product.

Due to the three-dimensional layouts, designers can fold or bend them as needed. This flexibility will help you fit components where there is limited space.

● Light Weight

If lowering weight is the primary objective of your project, Rigid-Flex PCBs are perfect for you. Rigid-flex boards are typically lighter than rigid PCBs with connectors and cables.

This further reduces the overall weight of electrical devices which will help you lift and transfer them safely and easily from one place to another. For this reason, they are more desirable.

● Better Reliability And Durability

With rigid-flex PCBs, you don’t need connectors and solder joints which reduces friction and chances of failure. spots.

Since you don’t need additional connectors, there will be less chances of interference with signals. Less interference and failure will automatically improve the overall reliability of your circuit.

● Better Signal Integrity

Because there are fewer interconnections and impedance mismatches, rigid-flex PCBs lessen the effects of poor signal integrity.

This is crucial when it comes to high-speed digital signals because you don’t want to compromise signal integrity. Overall, even enjoy the better signal integrity because of rigid flex.

● Fewer Assembly Steps

If you compare rigid-flex PCBs with conventional boards, you will notice that rigid-flex PCBs have fewer assembly steps since several rigid and flex circuit boards are combined together. These few steps will make the assembly a lot easier and you won’t have to put a lot of your mind on assembling everything.

Fewer steps are not only simple to perform but they also save your time and chances of failure.

● Effective Thermal Management

As you know, effective thermal management is absolutely crucial to avoid failure in PCBs. Rigid-flex PCBs do that for you. The flexible sections of rigid-flex PCBs make wiring more convenient.

Additionally, these simple and fewer processes in rigid-flex PCBs allow for effective heat dissipation.

● Offer Versatile Designs:

If you want to have unique and custom designs, rigid-flex PCBs will provide you with the right flexibility. You can create intricate designs and bend them however you like because of the flexibility of rigid-flex PCBs.

● Economical

Even though the initial costs for these rigid-flex PCBs may be higher, we are confident that you will save a considerable amount in the long run. A lot of it has to do with lower assembly costs, fewer components required, and increased reliability. All these factors will add to your possible savings.

Conclusion

With the development of lightweight, multi-functional and portable electronic products, such as mobile phones, wearable electronic devices, drones, aerospace equipment, etc., rigid flex PCBs will develop rapidly in the following years. And they can be designed and produced with more and more layer counts, and smaller and smaller drill and trace width. Rigid flex is the trending hot favourite and it’s obvious that rigid flex PCBs are going to be a lot more popular. PCB manufacturing services companies should be aware of the evolution of rigid flexible circuit boards and prepare in advance.

Also Read: Understanding The Flexibility Of Waves (WAVES) In Custom Token Creation